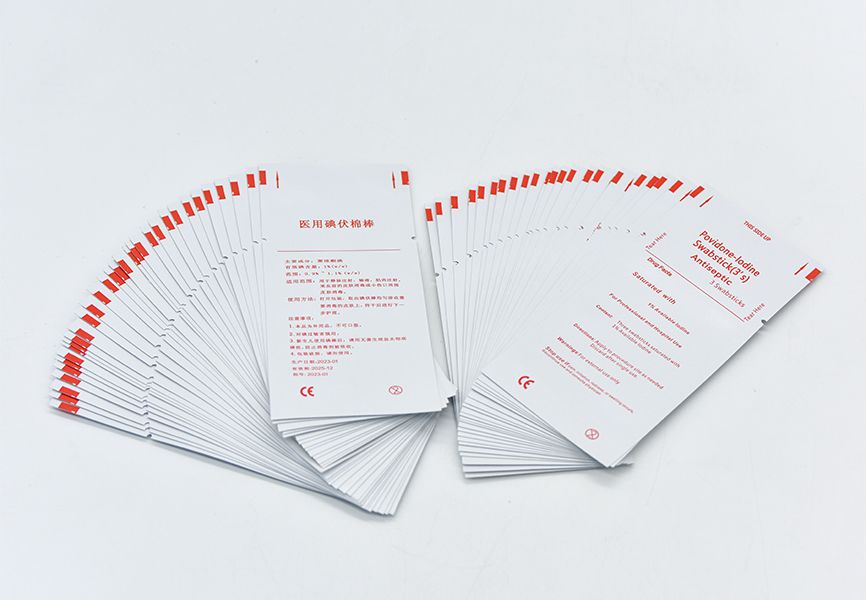

材質(zhì) Material:

BOPP/VMPET/PE MOPP/VMPET/PE PET/PE

簡介 Introduction

柔印是一種使用具有彈性的凸版的印刷方法,并以其具有良好的印刷質(zhì)量、適應廣泛的印刷材料、較高的生產(chǎn)效率、方便的操作維護、投資少、收益高、符合環(huán)保要求等一系列的優(yōu)點,使柔印成為各種包裝產(chǎn)品上選的印刷方案。

Flexo printing is a printing method using an elastic letterpress, and it has good printing quality, adapts to a wide range of printing materials, high production efficiency, convenient operation and maintenance, low investment, high income, and meets environmental protection requirements, etc. A series of advantages make flexo printing the printing solution of choice for various packaging products.

優(yōu)勢 Advantage:

環(huán)保要求嚴格

國家政策引導,倡導“綠色發(fā)展”,其主要著力點在于經(jīng)濟發(fā)展的方式,即強調(diào)經(jīng)濟發(fā)展與環(huán)境保護之間的協(xié)調(diào)性,將合理與理性原則貫穿于生產(chǎn)與消費的各個環(huán)節(jié),既能使經(jīng)濟快速發(fā)展,又能保護生態(tài)環(huán)境。柔版印刷本身就是一種綠色印刷方式,使用水性、UV、LED UV油墨。

生產(chǎn)效率高

柔版印刷的生產(chǎn)速度通常在100m/min以上,衛(wèi)星式柔版印刷設(shè)備的生產(chǎn)速度在300m/min以上,帶有絲印的組合印刷生產(chǎn)速度達60~70m/min,遠遠高于凸版印刷、間歇膠印等印刷方式的生產(chǎn)速度,生產(chǎn)效率大大提高。此外,一臺柔版印刷機通常只需要1~2個人開機,大大降低了人工成本。

調(diào)機損耗降低

隨著伺服技術(shù)和智能控制技術(shù)在柔版印刷設(shè)備上的廣泛應用,以及花瓣式柔印單元的普及,柔印設(shè)備的調(diào)機時間和損耗成本大大降低。

制版多樣化和快速化

隨著激光數(shù)字制版技術(shù)的應用,菲林制版已漸漸退出歷史舞臺,專業(yè)制版公司的制版速度提高,制版費用降低。同時,隨著水洗版材的質(zhì)量不斷提高,專業(yè)激光制版機的銷售費用也大幅度降低,越來越多的標簽印企開始自己配備制版設(shè)備并制版,使得制版時間和成本大大降低(接近凸版制版成本),適合中小批量訂單的使用。

印刷質(zhì)量大幅提高

數(shù)字技術(shù)、平頂網(wǎng)點技術(shù)的應用,橡膠版的使用,花瓣式柔印單元的普及以及高線數(shù)網(wǎng)紋輥的使用都使得柔印質(zhì)量大大提高,175LPI/200LPI的高網(wǎng)線數(shù)印刷已經(jīng)成為柔版印刷的標準。

投資門檻降低

國內(nèi)柔版印刷設(shè)備生產(chǎn)廠商的技術(shù)在不斷進步,且銷售價格相對便宜,越來越多的標簽印刷企業(yè)轉(zhuǎn)向投資國內(nèi)的柔版印刷設(shè)備,同時,進口柔版印刷設(shè)備生產(chǎn)廠商為了取得更多市場份額,也在降低銷售價格,大幅度降低了投資成本。

承印材料范圍廣

紙張(無論表面光滑或粗糙)、卡紙、瓦楞紙、薄膜、鋁箔、軟管等復合材料都可以采用柔版印刷方式進行印刷。承印材料范圍遠遠多于平版印刷、凹版印刷、凸版印刷等印刷方式。

色彩一致性強

由于柔版印刷采用短墨路傳墨方式,整個印刷過程只包含傳墨輥、網(wǎng)紋輥、印版輥和壓印輥,且通過網(wǎng)紋輥傳墨,可以保證同批次和不同批次印品之間的色彩一致性。

Environmental requirements are strict

Guided by national policies and advocating "green development", its main focus is on the way of economic development, that is, to emphasize the coordination between economic development and environmental protection, and to apply the principle of rationality and rationality to all aspects of production and consumption. The rapid economic development can protect the ecological environment. Flexographic printing itself is a green printing method, using water-based, UV, LED UV inks.

high productivity

The production speed of flexographic printing is usually above 100m/min, the production speed of satellite flexographic printing equipment is above 300m/min, and the production speed of combined printing with silk screen is 60-70m/min, which is much higher than that of letterpress printing, The production speed and production efficiency of printing methods such as intermittent offset printing are greatly improved. In addition, a flexographic printing machine usually only needs 1 or 2 people to start up, which greatly reduces labor costs.

Reduced machine loss

With the wide application of servo technology and intelligent control technology in flexographic printing equipment, as well as the popularization of petal-type flexographic printing units, the adjustment time and loss cost of flexographic printing equipment have been greatly reduced.

Diversified and rapid plate making

With the application of laser digital plate-making technology, film plate-making has gradually withdrawn from the stage of history, and the plate-making speed of professional plate-making companies has increased, and the cost of plate-making has been reduced. At the same time, with the continuous improvement of the quality of water-washed plates, the sales cost of professional laser plate-making machines has also been greatly reduced. More and more label printing companies have begun to equip themselves with plate-making equipment and plate-making, which greatly reduces the time and cost of plate-making (close to letterpress Plate making cost), suitable for small and medium batch orders.

Greatly improved print quality

The application of digital technology, flat-top dot technology, the use of rubber plates, the popularization of petal-type flexo printing units and the use of high-line-count anilox rollers have greatly improved the quality of flexo printing. 175LPI/200LPI high screen-count printing has become printing standards.

Lower investment threshold

The technology of domestic flexographic printing equipment manufacturers is constantly improving, and the sales price is relatively cheap. More and more label printing companies are turning to invest in domestic flexographic printing equipment. The share is also reducing the sales price, which greatly reduces the investment cost.

Wide range of printing materials

Composite materials such as paper (whether the surface is smooth or rough), cardboard, corrugated paper, film, aluminum foil, hose, etc. can be printed by flexographic printing. The range of printing materials is far more than that of lithography, gravure printing, letterpress printing and other printing methods.

Strong color consistency

Since flexographic printing adopts the ink transfer method of short ink path, the whole printing process only includes the ink transfer roller, anilox roller, printing plate roller and embossing roller, and the ink is transferred through the anilox roller, which can ensure the same batch and different batches Color consistency between prints.

復合紙卷材

復合紙卷材 復合紙卷材

復合紙卷材

首頁

首頁

產(chǎn)品

產(chǎn)品

電話

電話